NEWSLETTER

3/2024

Incentives for low carbon cement, concrete and concrete buildings

Low carbon products should increasingly play a role in tenders: But how?

Roadmaps and studies on decarbonisation and resource efficiency worldwide address the pathway to low carbon and near zero cement, concrete and concrete buildings. Besides the technical aspects, one of the prerequisites for climate neutrality clearly is a comprehensive policy package along the entire cement and concrete value chain to provide the right incentives and create an environment in which business activities can be geared to the needs of climate protection. One important instrument is the tendering of green products and buildings.

When building with concrete, the reduction of the CO₂ footprint can be addressed on three levels:

- Cement

- Concrete

- Component / Building

There are now classification options for all three areas.

Cement carbon classes

The question of when cements are CO₂ efficient, low CO₂, low carbon or simply ‘green’ is not easy to answer. The terminology shows that standardised definitions are important. Ideally, it should also be possible to apply these at European or international level. Ambiguities in the tendering process are not conducive to modern construction processes. According to the EU taxonomy, cements fulfil the requirements for ecological and sus-tainable management if no more than 469 kg of CO₂ per tonne is released during production. This is important for companies that are subject to a corresponding reporting obligation. This value could also be used in tenders. However, it offers no further possibility of differentiation, e. g. when it comes to the use of CEM II/C or CEM VI cements. Against this backdrop, an initiative of the G7 countries based on a methodology of the International Energy Agency (IEA) is important.

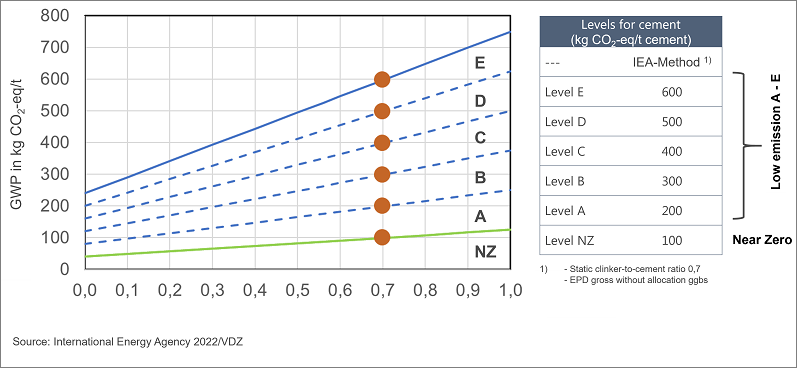

The G7-IEA approach

Figure 1 shows the methodology of the IEA approach. It provides CO₂ values for various classes of “low-emission cements”. Cements with increasingly reduced clinker content would fall into this category. The “near-zero emission” category would be reserved for cements in which the clinker comes from plants with CO₂ capture. With an average clinker factor of around 0.7 (e.g. Germany, global average), the corresponding classes can then be formed. In other countries, depending on the clinker factor, other class limits would possibly result.

Figure 1: Cement carbon classes with static clinker-to-cement ratio (example: 0,7)

Low carbon concrete

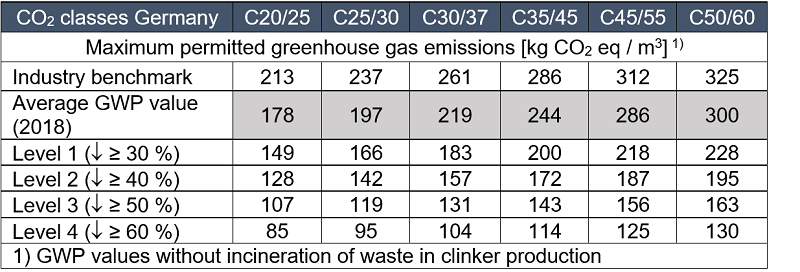

Transparent, product-related information about the CO₂ footprint for customers is an essential prerequisite for the use of CO₂-efficient concretes in construction. In addition to the instrument of environmental product declarations (EPD), the Concrete Sustainability Council (CSC) has been offering its own CO₂ module for this purpose, in which individual concretes can also be categorised according to CO₂ classes as part of CSC certification. The module defines four CO₂ classes, each of which represents the savings compared to a reference concrete for six concrete strength classes.

Table 1: Low carbon concrete classes acc. to Concrete Sustainability Council (CSC) Germany

The corresponding CSC certificate thus shows the CO₂ content for each product in a way that is easy for customers to understand.

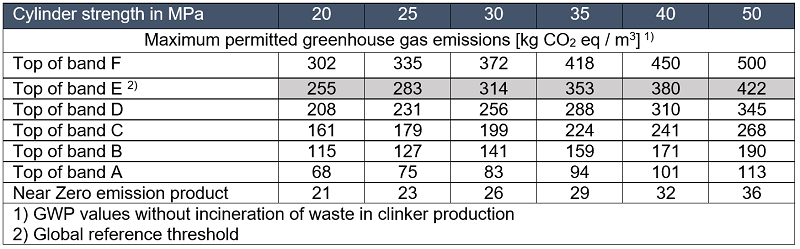

The global cement and concrete association (GCCA) is developing a two-stage approach for determining global warming potential classes of concrete:

- Definition of global GWP classes (A-G) based on data from larger member states (Table 2)

- Country-specific adaptation based on the applicable life cycle assessment rules

Table 2: Low carbon and near zero emissions concrete acc. to GCCA

Low carbon concrete structures

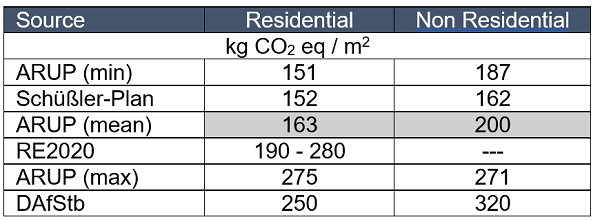

Values can also be specified for concrete structures. Table 3 shows values from various sources that have taken stock of the values that exist today. Finally, Table 4 shows targets that are being discussed in various places with regard to further optimising the carbon footprint of concrete structures. The values of the ambitious scenario of the ARUP study for residential buildings are in the same order of magnitude as the 70 % reduction class of the German Committee for Reinforced Concrete (DAfStb). In addition to the values for the overall structure, the DAfStb also defines targets for individual components. Ceilings are responsible for the largest proportion of CO₂ emissions in buildings with a load-bearing structure made of concrete.

Table 3: Benchmarks for embodies carbon of concrete structures

Table 4: Ambitions for embodies carbon of concrete structures

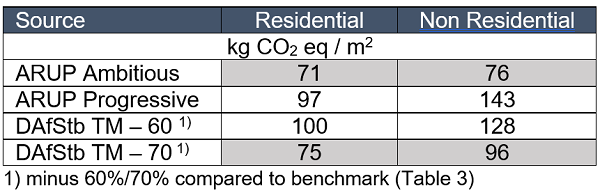

Figure 2 shows the classification into the reduction classes for a solid concrete ceiling, a hollow core concrete ceiling and a wooden ceiling. In addition to the status quo, the concrete ceilings also show values using Level 3 concretes according to Table 2.

Figure 2: Limit values for GHG emissions from ceiling systems with and without CO₂-optimised concrete

Practical issues in tendering

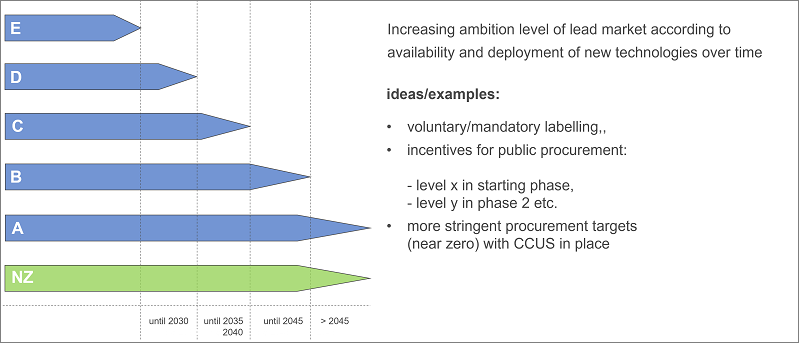

When inviting tenders, attention must always be paid to whether the corresponding technical solutions are available on the market in sufficient quantities. As a result, near-zero tenders today would largely come to nothing, as the carbon capture technology required for near-zero is not yet available. However, this will change over time. Figure 3 shows this in schematic form. An invitation to tender does not always have to specify a class. It is also possible to award the contract to the ‘best in class’ with reference to a classification system.

Figure 3: CO₂ thresholds need to reflect evolution of technologies (schematic figure)