Newsletter

1/2023

Monitoring of mercury emissions: Quality requirements and special challenges

Prerequisites for controlling abatement techniques and complying with emission limits

Emissions of mercury and its compounds from some industrial installations are limited across the EU by the Industrial Emissions Directive (2010/75/EU) and the associated BREF documents. In the industrial plants concerned, compliance with the specified emission limit values is monitored continuously or periodically. Numerous difficulties had to be overcome in the early days and it has been helpful that new, significantly improved types of emission monitoring devices have been developed by manufacturers in recent years. Discussions about lower emission limit values also made a review of the EN standards for mercury measurements necessary.

Mercury and its compounds have toxic effects on humans and the environment. Therefore, mercury emissions are limited and countries worldwide have committed themselves in the Minamata Convention aims to reduce anthropogenic mercury pollution on a global scale.

In the European Union, the Industrial Emissions Directive (2010/75/EU) and the associated BREF documents define the limit values and framework conditions for emission monitoring in the cement industry, especially for plants that co-process alternative fuels.

Mercury emissions are measured continuously or periodically, depending on the national regulations. Extensive experience exists regarding the use of mercury measuring devices, although numerous difficulties had to be overcome in the early days. It was helpful that new, significantly improved types of devices were developed by the manufacturers in recent years

Continuous monitoring

Continuous monitoring of mercury emissions is extremely challenging because mercury in the exhaust gas of a cement kiln can occur in different bonding forms. In general, a distinction must be made between elemental mercury [Hg(0)] and oxidised mercury [Hg(I) or Hg(II)].

The UV photometers used in all devices can only detect the elemental form of mercury [Hg(0)]. Therefore, the presence of oxidised mercury and its complete reduction to elemental form is generally the major challenge to the proper operation of a continuous mercury monitor.

To overcome these challenges, some plants are using new mercury CEMs which have recently been introduced to the market. These new devices follow two paths to ensure proper operation of the CEM: In one case, a thermal catalyst is used. At the same time, the sample gas is diluted to prevent contamination of the catalyst. This sample gas dilution also reduces possible cross-sensitivity effects due to other exhaust gas components.

A completely different approach is taken with devices that are equipped with a quartz cell which heats the sample gas stream to a temperature of 1000 °C. At such a high temperature, the mercury in the sample is completely reduced to its elemental form and can be measured directly in the photometer.

In addition, all new devices can also be optionally equipped with an automatic adjustment device, as the European standard EN 14181 requires regular quality control by the operator (QAL3). In this context, it should be mentioned that due to the IED, the application of the European standards is also mandatory for the calibration of CEMs.

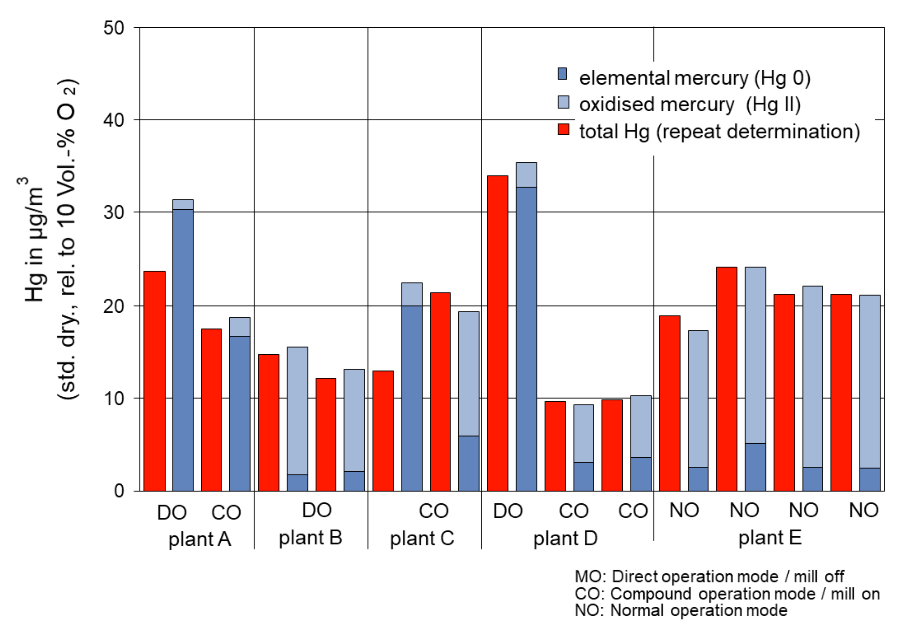

Figure 1: Results of mercury speciation measurements at different plants

Mercury speciation

Figure 1 shows an example of different, so-called speciation measurements in five different plants. Each set of speciation measurements was supplemented by a comparative measurement of the total mercury emissions according to the standard reference method (EN 13211). These additional measurements (red bars in Fig. 1) were necessary to assess the overall accuracy of the speciation. It could be clearly shown that the ratio be-tween elemental and oxidised mercury can be very different. So far, no correlation between the operating modes (mill off versus mill on) or other operating parameters and the binding form of Hg in the exhaust gases could be established.

Only the influence of the SCR catalysts on the ratio between elemental and oxidised mercury could be shown. The catalytic converter obviously leads to a shift from elemental mercury to the oxidised form. This is quite important information, as oxidised mercury can be more easily co-precipitated with dust particles than elemental mercury. The same observations have been reported from power plants.

Nevertheless, controlling or perhaps even influencing the binding form of mercury is a crucial point for future progress in monitoring as well as in reducing mercury emissions.

Mercury emission limits

Emission limits for mercury range between 0.003-0.10 mg/Nm³, with a few exceptions. In the EU, industrial mercury emissions are regulated by the Industrial Emissions Directive (IED), which limits them to 0.05 mg/Nm³ for alternative fuel co-firing furnaces with a sampling period of 30 minutes to 8 hours.

In the United States, mercury emissions are limited based on the amount of clinker produced and average 27.5 kg per million (metric) tonnes of clinker produced for existing kilns. Depending on the conversion factor, this corresponds to about 8 - 13 µg/Nm³. For new kilns, the limit is even stricter at about 3 - 5 µg/Nm³ (i. e. 11.5 kg per million tonnes of clinker produced). It should be noted that these limits are based on a 30-day moving average, which is supervised by long-term measurements using sorbent traps.

Due to these developments, a revision of the current EN standards for mercury measurements has been started and partly already completed in the EU which is to be transferred into practical application in the coming months.