Newsletter

1/2021

Resource efficiency of the concrete sector: Rethinking the proven

How to meet the demand for resources when building with concrete in the future

As the world continues to urbanise, many countries will face challenges in meeting the needs of their growing urban populations, including for housing, transportation, energy systems and other infrastructures. Concrete makes a valuable contribution to this worldwide. Regional bottlenecks in the supply of raw materials for the production of cement and concrete already exist today. How does the concrete sector face this challenge in the long term?

The use of alternative raw materials represents a key contribution for substituting primary raw materials and thus plays an active role in conserving resources. However, the supply of alternative raw materials is not directly coupled to their demand. Thus, for example, the volume of recycled building materials is primarily determined by demolition activities, which in turn are determined by the intensity of new construction activities.

Demand for mineral resources

At present in many European countries most of the mineral building waste is recycled or recovered. In this respect, only a slight increase in the already high recycling/recovery rate of building waste materials would be possible. Industrial by-products are also widely used in the mineral and building materials industry. In the ECRA study “Closing the loop” from 2015, this was illustrated using the example of the Netherlands. On the input side, only around 14% of the aggregates can be covered by recycling material, whereas mineral construction waste is almost completely recycled. If the proportion of recycling material in concrete is to be increased, the material would have to be removed from earthworks and road construction. More primary material would then have to be used there. If this also increases the preparation effort or the transport distance, this might not always be the best solution from the LCA point of view. Against this background, the question of how to meet the enormous demand for concrete structures without a further significant increase in the demand for natural resources arises.

Innovations in the resource efficiency of the concrete sector

Resource efficiency can be implemented at three levels:

- Optimised mix design, possibly including secondary raw mate-rials

- The lowest possible concrete content in the structure component without loss of technical performance

- Flexible layout design for the longest possible use

If these approaches can be combined, the reduction in the use of resources may be even greater. Both with known technologies and with new approaches like 3D printing, gradient concrete etc. we need to ask what the potentials are and what obstacles may hinder a broad application in practice today or tomorrow. Why are known methods of packing density optimisation in daily concrete production rarely used? What incentives could change this? How can architects/designers make greater use of solutions such as concrete hollow core slabs, in which only half as much concrete is needed compared to the “classic” reinforced concrete solution?

Portland cement clinker as an example

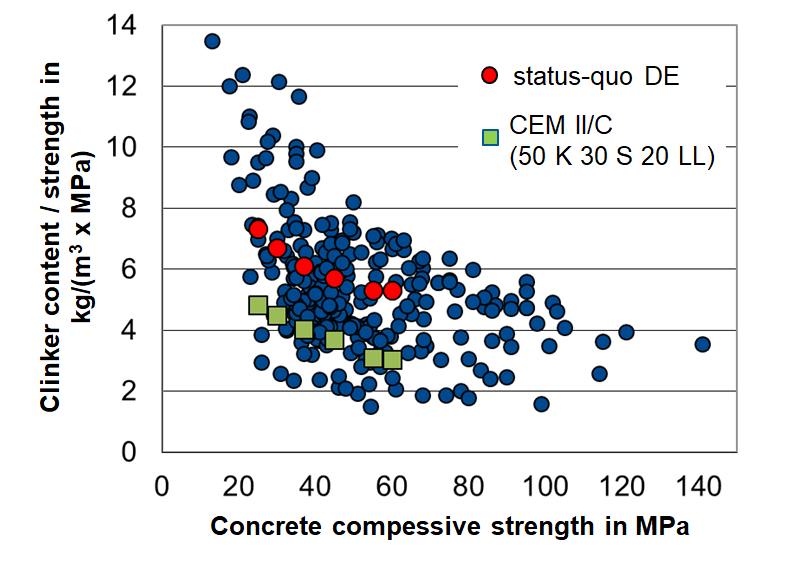

An indicator for the development of the CO₂ intensity of the cement industry is the clinker factor. This parameter does not allow a direct link between the ecological performance and the technical performance of cement and concrete. Therefore, in various publications performance-related parameters are also found, such as the binder or clinker intensity in kg/(m³ x MPa) or the CO₂ intensity in (CO₂/m³ x MPa). The latter describes how much CO₂ is allocated to a cubic metre of concrete of a defined strength. With increasing concrete compressive strength, specifically less clinker is required, as the clinker is used more efficiently. Particularly in the area of conventional concrete compressive strengths (e.g. C20/25 - C30/37), the range of clinker intensities which these concretes exhibit is considerable. Fig. 1 shows the mean clinker intensity of concretes of different strength classes with the example of Germany against the background of a data collection by VDZ.

If, for example, the use of CEM II/C-M cements were at least implemented for concretes of the exposure classes XC1-XC4 and XF1, the clinker-intensity and with that the CO₂ intensity of these concretes would be reduced by approx. 25%.

Figure 1: Clinker intensity in relation to concrete compressive strength (data collection and scenarios by VDZ).

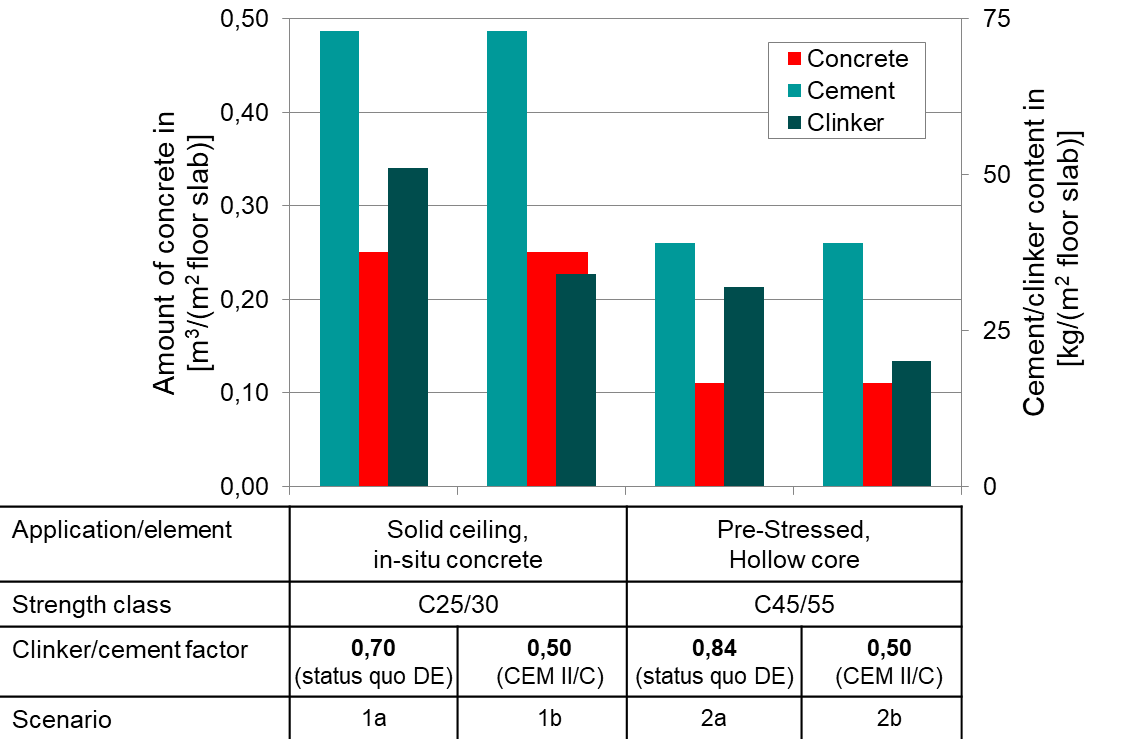

From clinker efficiency in cement to clinker efficiency in building

Very large quantities of concrete are used to manufacture floor slabs for residential and commercial buildings. It therefore makes sense to further improve clinker efficiency, especially in these applications. On the one hand, as indicated in Fig. 1, this can be achieved by reducing the clinker content in ready-mixed concrete of normal strength (C25 / 30 being the most frequently used strength class in ready-mixed concrete) in a solid ceiling with 0.25 m³ concrete / m² floor slab (Scenario 1b). Alternatively, a higher strength concrete (C45/55) can be used in a hollow core slab as a pre-fabricated element (Scenario 2a) (Fig. 2).

Due to the lower proportion of concrete in the hollow core slab or the pre-stressed element, a similar clinker content per m² of floor slab is achieved despite the higher clinker content in cements for precast concrete. The question for the future is: could clinker-efficient CEM II/C-M cement also be used for applications with high demands on strength development (Scenario 2b)?

Figure 2: Concrete-, cement- and clinker intensity of floor slabs

Innovative technologies

In the past years, digital fabrication with cement-based materials has aroused major interest in the architecture and construction industry. The research activities in this field have increased exponentially and various sophisticated solutions for concrete 3D printing are being developed worldwide (Fig. 3). Opportunities and challenges for the practical applications of these technologies will need to be discussed with partners all along the value chain. The same applies for example for gradient concrete.

Figure 3: Resource efficient concrete components - An overview of technological approaches