NEWSLETTER

1/2024

The role of performance and descriptive-based approaches in standards

Descriptive approaches and performance approaches both have their pros and cons

In the course of discussions which measures can best support the decarbonisation and resource efficiency of cement and concrete, the term "performance" comes up very often. Are performance-related concepts a “cure-all”? The closer look reveals: Descriptive approaches and performance approaches both have their pros and cons.

The current standards for cement and concrete in Europe contain three types of concepts or approaches:

- Requirements of the composition,

- Parameters to be adhered to (“passed”),

- Performance-related characteristics.

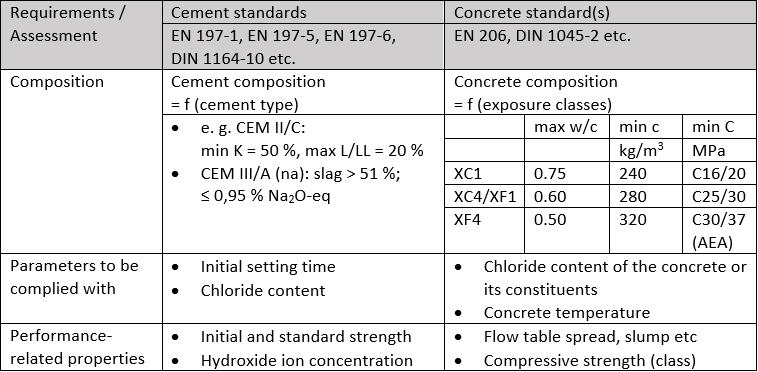

Table 1 gives an overview about these concepts in the cement and concrete standards. In the discussion about CO₂ mitigation and resource efficiency, the composition (descriptive requirements) is repeatedly mentioned as an obstacle to innovation. Performance-related evidence is required. What is the composition of cement and concrete needed or used for today?

Scenarios for new concepts

The cement type acts as an “indicator” for the cement composition and forms the basis for the application rules for the cements according to exposure classes e. g. in the national application documents to the European concrete standard EN 206. If the cement standard would not specify the composition, then

- the composition has to be specified in the application rule or

- (durability-relevant) performance evidence would have to be integrated into the cement standard or the concrete standard.

Exceptions are applications without durability requirements, e.g. dry interior components, or where strength is an “indicator” of durability

When looking for an example how a cement standard with more performance elements – even for durability - would look like, reference could be made e. g. to EAD 150001-00-0301.

The main elements are:

- Description of the product

- Intended use(s)

- Essential characteristics

- Methods and criteria for assessing the performance

- Assessment and verification of constancy of performance

Essential characteristics are e. g.:

- Early strength/Standard strength

- Cement composition

- Initial setting time

- Soundness

- Sulfate content

- Chloride content

- Carbonation of concrete

- Resistance to chloride penetration

- Freeze-thaw resistance without de-icing agent

- Freeze-thaw and de-icing salt resistance

- Content and/or release of dangerous substances

Results are declared and partly assessed by threshold values or an evaluation background. The extent to which decarbonisation and resource efficiency would be supported by using these approaches in standards for cement and concrete depends on the specific design of the regulations. This is shown below.

Durability performance

The introduction of performance-related concepts as an alternative to descriptive rules can be a very useful tool. The regulations for concrete roads in Germany have for several years now required performance tests of concrete to avoid a damaging alkali-silica reaction. The situation is similar with concrete railway sleepers. In both cases, these concepts serve well: damage has been reliably avoided since their introduction. This is an important contribution to the sustainable use of concrete. In large parts of concrete construction, however, durability is currently dealt with through descriptive rules (maximum water-cement ratio, minimum cement content, minimum compressive strength, minimum concrete cover). The next edition of Eurocode 2 now also includes a concept for performance-related proof of durability with the “Exposure Resistance Classes, ERC”. Whether and how this concept could be implemented in CEN member states, two aspects are important here: contradictions to the descriptive approach should be limited and what has already been achieved in decarbonisation and resource efficiency must not be counteracted. This is discussed using the example of carbonation.

Descriptive vs. Performance

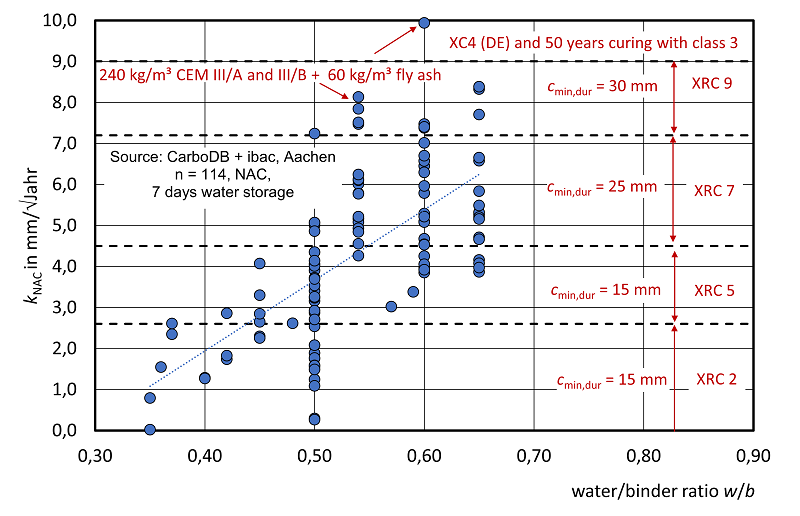

Several countries allow e. g. the use of cements with low clinker content and high amounts of slag. This has been a significant contribution to the mitigation of CO₂ for many decades already. Concrete with these cements show a relatively high carbonation rate when tested according to EN 12390-10. Figure 1 shows data compiled within a database on carbonation. Values with w/c of 0.60 are in a range > 10 mm/a0.5. Con-cretes with this performance are not even mentioned in the new EUROCODE. To further use such concrete to save CO₂ would mean that the water/cement ratio would have to be lower and the concrete cover would have to be higher than today. Both measures are not really a benefit for the reduction of CO₂ in concrete structures. For that reason, for the time being no consensus has been reached in the efforts to prepare a new part EN 206-100 as to define Exposure Resistance Classes in the concrete standard.

Outlook

The introduction of performance-related concepts as an alternative to descriptive rules can be a very useful tool. They serve quite well already e.g. when using ASR-performance test to avoid deterioration or in the procedures for new products within European Assessment Documents. All stakeholders along the value chain must now decide together under which conditions a rollout in the standards for cement and concrete makes sense. Standards for cement and concrete could contain an appropriate combination/mix of descriptive regulations and performance-related approaches:

- Robust and easy to use deemed-to-satisfy rules for the main cements and concretes in the market

- Specific rules for very low clinker cements/concretes

- Performance-based specifications for concrete in different applications